Fungus Resistant Flexx-Sil™ Cables

Valencia, CA; April 7, 2021: In 1998, Cicoil developed an ultra-pure cable jacketing material which is ideally suited for highly flexible and high-performance flat cable applications. This Cicoil-exclusive material named Flexx-Sil™, is a unique, engineered polymer that includes the best aspects of silicone rubber, without the impurities and additives found in common silicone polymers. Combining Flexx-Sil™ with our exclusive extrusion process produces the most advanced cable jacketing material available in the marketplace.

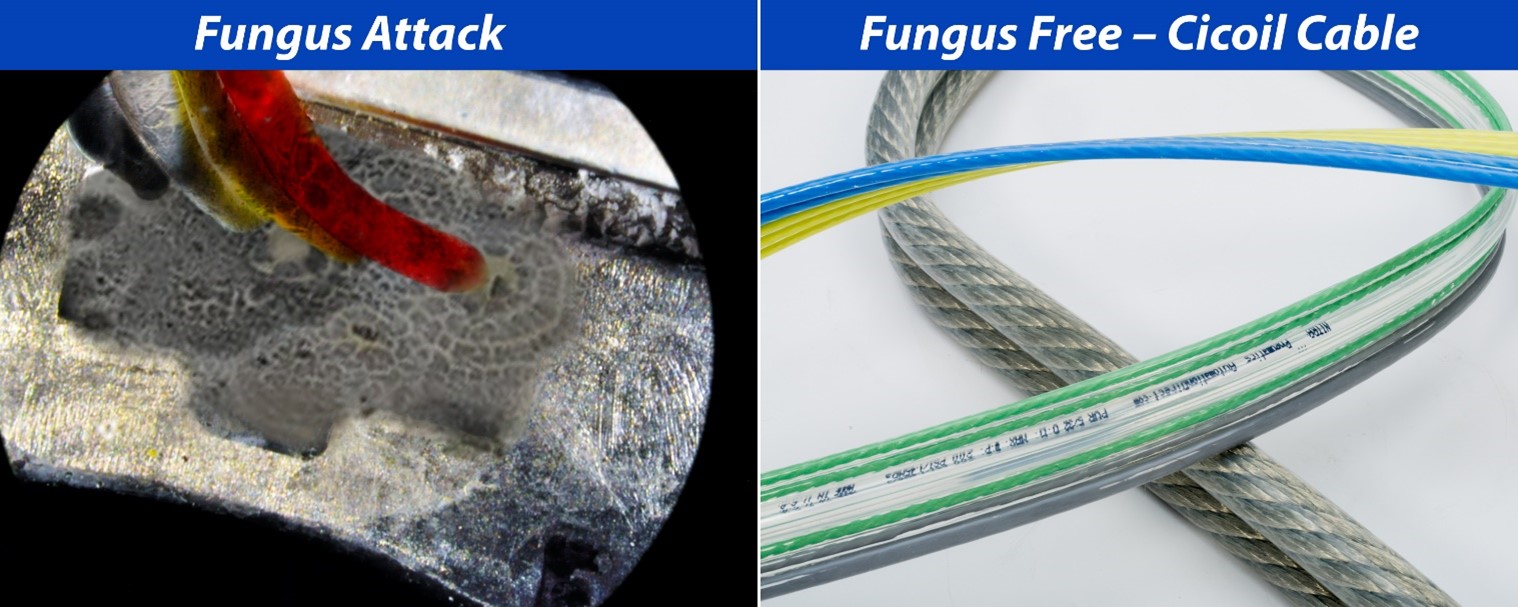

Cicoil’s Patented Flexx-Sil™ rubber offers a unique combination of mechanical and chemical properties that organic elastomers are incapable of. The backbone of most rubber materials incorporates carbon-carbon bonds, whereas Flexx-Sil™ is carbon free. Unlike other elastomers, the inorganic foundation of Flexx-Sil™ makes it highly resistant to many chemicals, harsh weather, and fungus. Flexx-Sil™ rubber is also resistant to sunlight, ozone, hot & cold temperature fluctuations and UV exposure, whereas carbon containing elastomers are susceptible to attack.

Most common wire and cable jacketing materials are vulnerable to mold and fungus attack because they are made from hydrocarbon-based compounds. For example, Fungi feed on organic matter such as plastics, not because they can digest them, but because most plastics are esters of fatty acids, and therefore can be eaten by microorganisms. The plastic itself is damaged by the acids produced by the microorganisms, but the main issue is that the material is made brittle due to the extraction of the plasticizers. Eventually the plasticizers completely disappear, leaving a plastic with significantly decreased mechanical properties.

Since it is not a nutrient for fungus, Flexx-Sil™ can be used in wet, hot, and humid environments, and it is not possible for this inorganic polymer to support the growth of fungus. Given the composition of our Flexx-Sil™ rubber, microorganisms such as mold, mildew, viruses, fungus, and bacteria will not adhere to our cables, so no fungicide additives are used or needed. With its resistance to IPA, alcohol, hydrogen peroxide, autoclave, and other germ-killing chemicals, Cicoil’s Flexx-Sil™ jacketed cables can be easily and quickly sanitized against COVID-19 and other harmful viruses as well.

Due to these beneficial features, Flexx-Sil™ jacketed cables can be utilized in the food & beverage, pharmaceutical processing, medical instrument, aircraft, cable, implantable medical devices, and Space applications without any worry of intrusion by fungus.

Cicoil's Crystal-Clear, Class 1 Clean Room Rated Flexx-Sil™ Cables are low outgas, RoHS & REACH Compliant and are cured continuously, with no debris or material impurities in an automated, climate-controlled environment. The cables also meet MIL-HDBK-454, Mil-STD-810, MIL-E-5272, and RTCA DO-160G section 13 for Fungus Resistance.

For more information, download a copy of our Fungus Resistant Cables flyer: https://www.cicoil.com/images/pdf/product-literature/Fungus-Proof-Cicoil_V2_04-07-21.pdf

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for over sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications, including aircraft fuel control cells, semiconductor automation, and the International Space Station. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information or call 661-295-1295 to speak to an application engineer.