The SPACE Cable that Saved Space

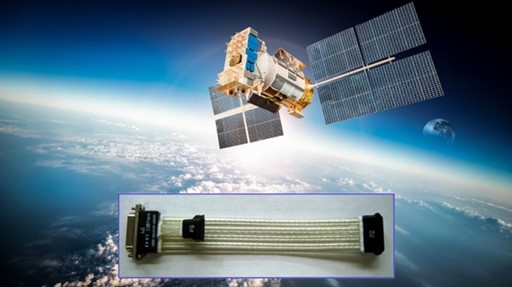

Valencia, CA; October 22, 2019: Cicoil, the leading manufacturer of high performance Flat Cables, is pleased to announce the addition of its New Case Studies Section to its web site. The first study entitled “The SPACE Cable that Saved Space” showcases how Cicoil’s lightweight cable assemblies provide maximum space efficiency in extremely tight spaces, including the world’s smallest satellites.

The customer, a manufacturer of CubeSat’s, a class of spacecraft called nanosatellites, was having difficulty in finding a flexible Camera Link cable that could fit inside a very small space. Each CubeSat measured about four inches on each side and weighed less than three pounds, with a volume of about one quart. Besides consuming minimal space, the Camera Link Cable would need to provide uninterrupted performance, very reliable EMI protection and have the capability to survive the harsh rigors of Space travel.

After evaluating several round Camera Link cable options, none of the designs could provide the necessary requirements for the customer’s application. After reading about Cicoil’s exceptional history and success stories with the U.S. Space Program, the customer reached out to Cicoil to help in solving its challenge in finding a cable that would meet its demanding requirements. Fortunately, Cicoil was able to offer a flat, lightweight Camera Link cable that would not only address limited space concerns, but was able to provide EMI protection, mission critical reliability and survive exposure to the harsh environments of Space.

Unlike, stiffer and bulkier round Camera Link cables offered by other manufacturers, Cicoil offered a dual shielded design, incorporating an inner foil shield to provide 100% coverage, and an overall tinned copper braid with 90% coverage. A durable, yet flexible PFA insulation is layered between each shield, which protects the inner foil shield from making contact with the outer tinned copper braid. The flat design requires less space than round cables, offers ultra-fine conductor strands and reduced weight, while providing unsurpassed electrical/signal attributes. Parallel conductors and Cicoil’s proprietary Flexx-Sil™ Jacket provide for mechanical strength, superior flexibility with durability under continuous motion.

As a bonus to its Camera Link cable solution, Cicoil was also able to provide fully terminated, plug & play assemblies, which are certified to the IPC 620 Space Addendum. In addition, the flame retardant + halogen-free cables met all of the customer’s test requirements: outgas, bend radius, flex cycles, Camera Link protocol, electrical, signal; and resistance to vibration, shock, rigors of supersonic flight, radiation, UV light, ozone, sunlight, corona discharge, mechanical stress and extreme temperatures (-65°C to +260°C).

Cicoil’s Cables are Space Flight Approved by NASA, Class One Clean Room Rated and are cured continuously, with no debris or material contamination in an automated, climate controlled environment. In addition, the non-particulate generating cables exceed the outgassing requirements of ASTM E595 / NASA 1124 and are also excellent for use in vacuum environments.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for over sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications; including aircraft fuel control cells, semiconductor automation, and the International Space Station. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.