Cicoil Case Study

Good to the Last Drop

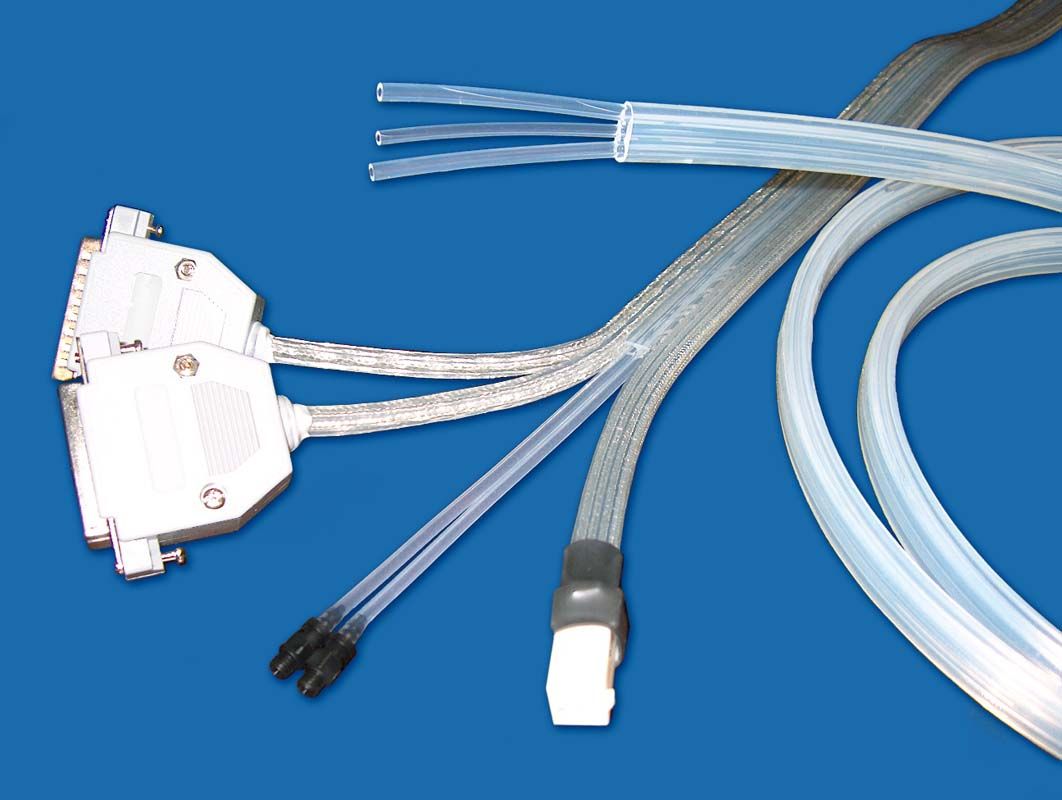

Electrical + Tubing Combined in One Flat Combination Cable for Blood Analysis

Background

Customer manufactures medical diagnostics systems that incorporate multi-axis position systems. Blood sample vials are picked and placed, blood is extracted from vials and placed on slides where they are then stained with reagents, and cell images are examined & diagnosed. Reagents travel through tubes, which are typically placed near electrical wires/cables.

Challenge

Multiple cables and tubes are placed inside cable tracks where friction and entanglement cause performance failure to each. Customer wanted to isolate tubes from cables and also desired to eliminate the 2-foot long cable tracks, which are loud, generate particulates, and take up space. These changes were necessary to increase efficiency and reduce the size of their diagnostics system.

Solution

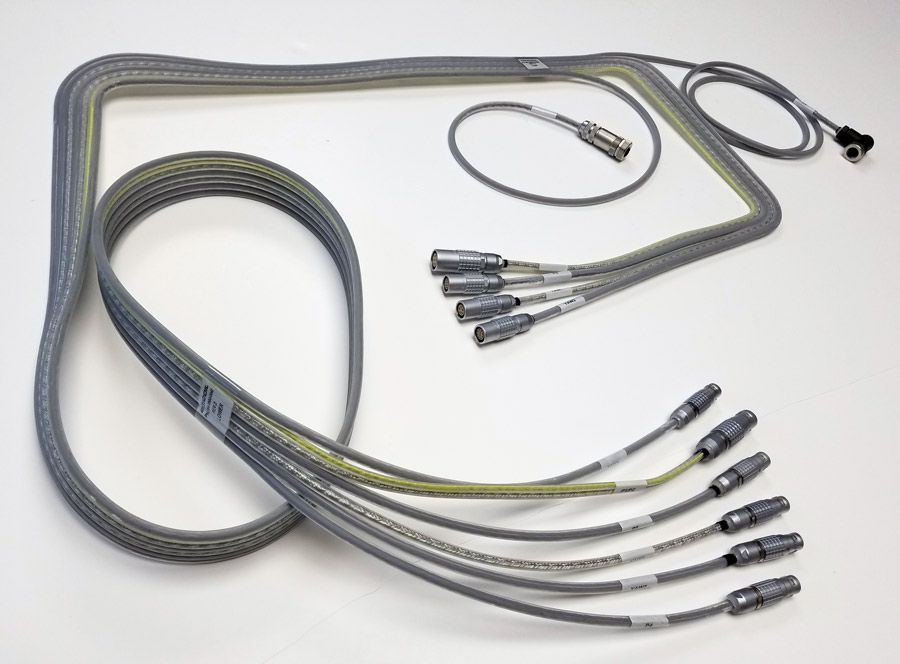

Cicoil offered continuous motion cable that was able to incorporate multiple tubing lines with various electrical conductors. The flat profile cables are self-supporting in lengths up to nearly 3-feet, which also enabled the customer to eliminate the loud, space consuming, particulate generating and costly cable tracks.

Benefits of Cicoil Flat Cable

- Integrated PTFE tubing within flexible flat cable for organized and efficient pneumatic grippers, liquid dispensing, and vacuum applications

- Flexx-Sil™ flat cable provides tens of millions of cycles in flexing applications, resulting in equipment uptime and Reliability

- Cicoil’s Flat cables are resistant to radiation, autoclave, steam, de-ionized water, alcohol, UV light, hydrogen peroxide, saline and many chemicals

- Continuous flex flat cables are so durable they can eliminate costly cable tracks in many applications

- Extreme flexibility reduces the space needed for cabling, thereby reducing equipment size

Results

Replacing multiple, unorganized wires & cables + tubing lines, with organized flat cables allowed customer to reduce the size of their equipment, eliminate costs, increase product reliability & uptime and become more competitive within the automated medical diagnostics market. In addition, Cicoil was able to provide fully terminated assemblies with the customers preferred connectors and fittings for the tubing as well. Cicoil’s cable assembly technicians are certified to IPC J-STD-001, and IPC-620, for cable soldering and crimping. 100% of Cicoil cables are electrically inspected for all point-to-point and electrical values, ensuring that each and every cable assembly meets 100% of the quality standards required by the most critical application.

Per the customer:

Per the customer:

“We needed to reduce the overall size of our diagnostics equipment, clean up the routing of cables & tubing and make a more efficient system. Much frustration was caused from our current setup and fortunately we found Cicoil, and they offered more of a solution than we even anticipated.”

Speak with one of our Flexible Cable Solutions Specialists to discuss your inflexible application requirements. Our team of experts will help with all of your cabling, assembly and value-added needs.

A Few Related Customers