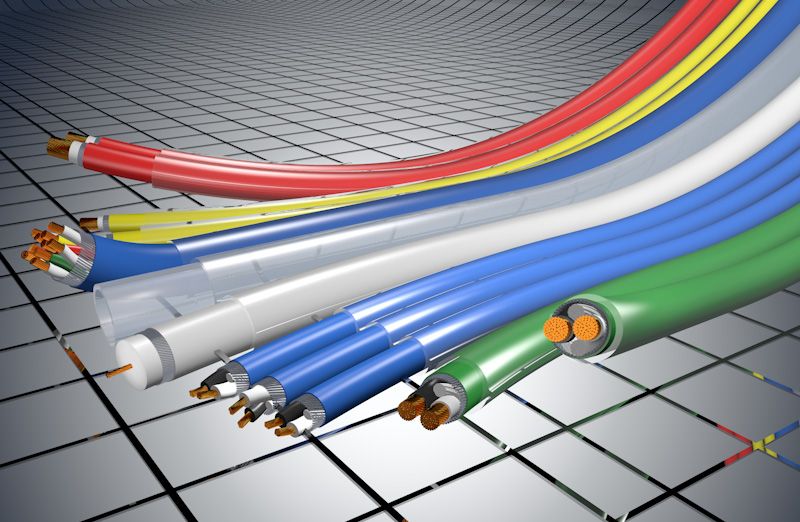

Extruded Cicoil Flat Cables

Cicoil Flat Cables feature computer-controlled placement of conductors within a one-piece encapsulation. Every conductor is held in precise alignment for controlled movement. This configuration provides lower weight, smaller volume, and enhanced electrical/signal properties, compared to their round counterparts.

vs

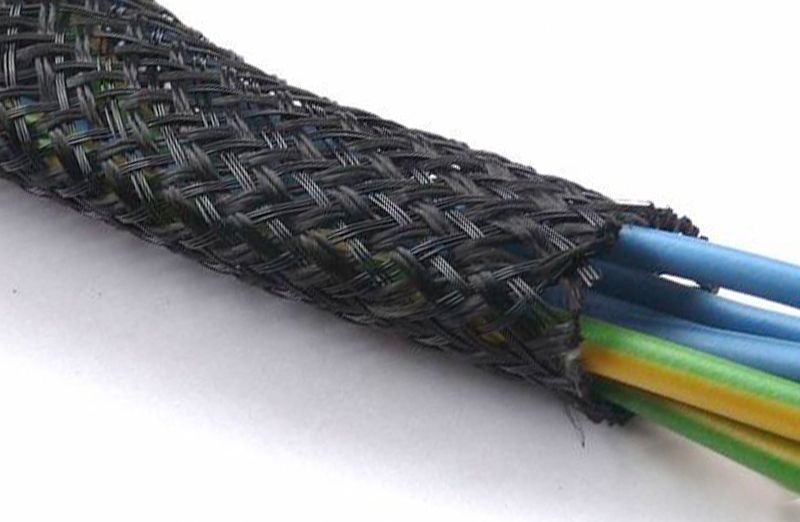

Woven Braid Cables

Cables with woven braid jackets can provide some very interesting colors and patterns, but are limited in their ability to protect the conductors within. They are susceptible to degradation from environmental and substance exposure, and are easily damaged. Loose conductors within can become twisted and kinked when motion is introduced.

Extruded Flat Cables

vs

Woven Braid Cables

EXTRUDED FLAT CABLES

QUALITY

WOVEN BRAID CABLES

Computer controlled flat cable extrusion process allows for the same exact cable every time you order it and the crystal clear jacket is free of convolutions. Cable is cured continuously, with no debris or material contamination in an automated, climate-controlled environment.

vs

Woven design provides an outer textile material to cover a flat layer of inner wires and twisted pairs. However, the inner components are not separately encased, so they will not be in the exact same place every time. Inner components can be exposed to contaminants.

The tear-resistant outer Flexx-Sil™ rubber jacket is also self-healing from small punctures. Anti-kinking design is tangle free and excellent in constant motion and extremely tight bend radius applications.

vs

The textile material is exposed to harsh operating environments. During flexing and tight bend radius applications, the woven cables are prone to kinking and fatigue.

EXTRUDED FLAT CABLES

STRENGTH & PERFORMANCE

WOVEN BRAID CABLES

Cable is solid, one-piece construction. Strength is enhanced by the fact that all conductors and insulation equally share tensile loads. Rounded edges of cable absorb stress as well.

vs

Flat woven cables do not have rounded edges and lack the mechanical strength of a solid, one-piece extruded design. Conductors don't share equal tensile loads.

Each element in Cicoil flat cables are completely surrounded by Flexx-Sil™ rubber, ensuring that they do not rub against each other and wear during operation.

vs

Inner components are not separately encased within their flat profile. They will rub against each other during any movement, which results in wear and tear.

Outer jacket with a durometer of Shore A65 is similar to the heel of a shoe, and provides excellent mechanical protection to inner wires.

vs

The outer sleeving may provide some protection of the inner wires, but they do not provide resistance to shock, vibration, and mechanical stress.

EXTRUDED FLAT CABLES

VERSATILITY & COST

WOVEN BRAID CABLES

Flexx-Sil™ jacketing is self-healing from small punctures, and cable damage can easily be repaired in the field.

vs

Once the outer woven wrap is damaged, the inner components are exposed, leading to damage, failure, and replacement.

When bent in the same plane of its thin cross section, Cicoil Flat Cables have inherently more flexibility than round cables. The spacing of conductors never changes as the cable moves, so each conductor flexes the same amount in the same plane.

vs

Woven cables are not made for constant motion applications. When flexed, the inner components will corkscrew, tangle, and kink, leading to cable failure.

The crystal clear Flexx-Sil cable is easy to inspect and provides excellent aesthetics.

vs

With the exception of air gaps, woven wraps cover the inner components, providing no visibility and leaving the cable prone to undetectable defects.