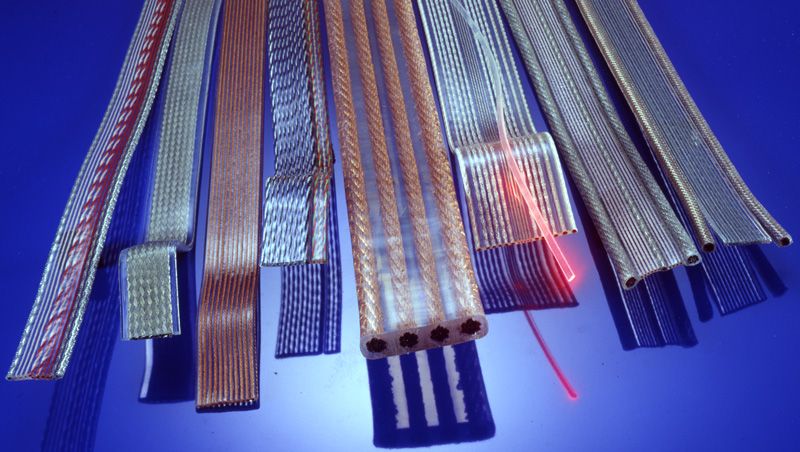

Cicoil Flat Cables

Designed for Repetitive Flex: Cicoil flat cable uses ultrafine wire in its conductors, and a proprietary jacketing material called Flex-Sil™ that does not merely sheath the conductors, it fully encapsulates each one individually. Conductors run in parallel, remaining in the same plane. The result is a nominal life expectancy of more than 10,000,000 flex cycles.

Flat Cables also excel in high-density applications, and provide more efficient cable management.

vs

Extruded Round Cables

Repetitive Flex Failure: The geometry of round profile cable presents enough difference between the outside and inside radii of a bend to produce both flex stress on the jacket and compression on the individual conductors inside. The result is deterioration, corkscrewing, and failure.

Round cables add another design and manufacturing task: cable management. Imagine, all these separate round cable could be combined into a single flat cable.