Extruded Cicoil Flat Cables

Cicoil Flat Cable precision and performance... Beautiful.

vs

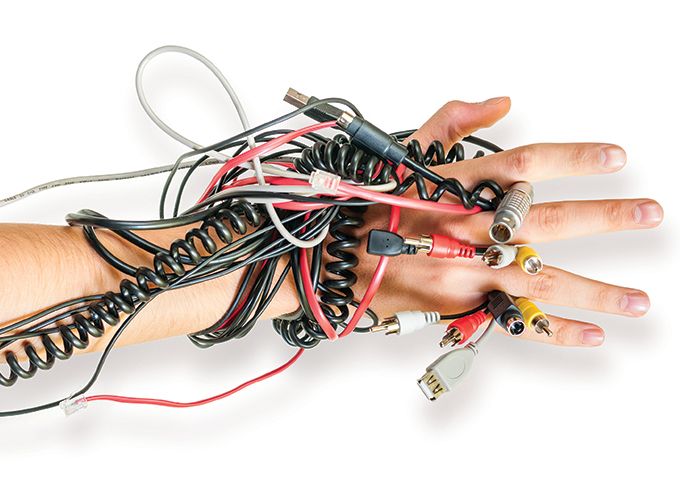

Loose Wires

Loose Wires... Not so much.

Extruded Flat Cables

vs

Loose Wires

EXTRUDED FLAT CABLES

QUALITY

LOOSE WIRES

The simplicity of flat cable with its parallel conductor geometry eliminates many of the common sources of wiring error and malfunction. Registration of the conductors is one-to-one with the terminating connector or board so that proper contact assignment is almost automatic.

vs

Loose wires, aka spaghetti wires, in bundles become very messy, are hard to identify and are prone to wiring errors and malfunction.

Computer controlled flat cable extrusion process allows for the same exact cable every time you order it and the crystal clear jacket is free of convolutions. Cable is cured continuously, with no debris or material contamination in an automated, climate-controlled environment.

vs

Wires are exposed to harsh environments, pulling, abrasion, and damage.

The tear-resistant outer Flexx-Sil™ rubber jacket is also self-healing from small punctures. Anti-kinking design is tangle free and excellent in constant motion and extremely tight bend radius applications.

vs

Wires are exposed to punctures, kinking, entanglement, and impede each other's performance in flexing and bending applications, which leads to damage and failure.

EXTRUDED FLAT CABLES

STRENGTH & PERFORMANCE

LOOSE WIRES

Cable is solid, one-piece construction. Strength is enhanced by the fact that all conductors and insulation equally share tensile loads. Rounded edges of cable absorb stress as well.

vs

Scattered wires in a loose bundle operate independently of each other. Individual wires are exposed to greater tensile loads and added stress.

The flat form factor of Cicoil cables provides better heat dissipation than round cables because there is more surface area for a given volume.

vs

Wires wound into a bundle plus an outer protective covering, so exposure to heat dissipation can become an issue and cause wire failure.

Outer jacket with a durometer of Shore A65 is similar to the heel of a shoe, and provides excellent mechanical protection to inner wires.

vs

Wires and pairs are exposed to mechanical stress and abrasion.

EXTRUDED FLAT CABLES

VERSATILITY & COST

LOOSE WIRES

Flexx-Sil™ jacketing is self-healing from small punctures, and cable damage can easily be repaired in the field. Inner wires are completely encased in Flexx-Sil™ jacket.

vs

Loose wires can easily be damaged from exposure to the application they are utilized in, so require expensive tubing, sleeving, or conduit to protect them as well.

Simple Plug-n-Play cable saves time and money.

vs

Expensive cable management products are required to organize loose wire bundles, which involves more time-consuming labor, costs, and potential for error.

The crystal clear Flexx-Sil cable is easy to inspect and provides excellent aesthetics.

vs

Inspection of bundled wires takes time, and additional materials required to hide the unorganized bundle increase costs.